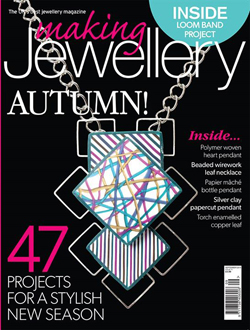

Issue 71 of Making Jewellery magazine comes out today {21st Aug} featuring lots of fab projects including my first torch enamel project for a magazine. I've done several wirework step-by-steps for Bead magazine in the past but never anything involving enamel so it was a treat to do it.

I was emailed by Sian the editior of Making Jewellery a few months ago asking if I'd like to contribute a project. I said yes {of course!} then immediately wondered if I was going to be asked to make a wirework piece. I don't make much wirework jewellery these days so was really pleased to be told I could do a project using torch enamelling as they hadn't had any torch enamelling projects in the magazine before.

After finding out the theme for the issue was going to be "autumn" I decided to go for a copper leaf enamelled in a blend of lovely autumn-ish colours and made a pendant as the main piece and a pair of earrings and bangle charm as the two "extras".

That isn't a photograph of me by the way! {I think it's Abby Clancy, I was busy that day.....}

I took some photos of the pieces I made before sending them off to the magazine to be photographed and made a collage......... because I like making collages :D

I was pleased to see Kristen, a fellow jewellery maker whose blog K S Jewellery Designs I follow, also has a project in this issue! She went with the leaf theme too and made a very pretty silver and bead wirework necklace and pendant.

It's nice to be in good company!

Congrats on being featured and I love that little cut on the leaves

ReplyDeleteThanks Divya :D

DeleteBeautiful! Congrats!

ReplyDeleteHey Tracy!

ReplyDeleteI saw your lovely project in Making Jewellery today. I'm in there too - see page 62!

Kristin :)

Awww... thanks for the mention Tracy. I was so excited to see you in Making Jewellery too and see you blogged about it, I didn't fully read your post!

DeleteKristin :)

That's ok Kristin :D

DeleteWell done on the Magazine Article and fabulous choice to showcase. The colours are beautiful!

ReplyDeleteHeather :)

Thanks Heather!

DeleteCongratulations on the feature Tracy! It looks great.

ReplyDeleteThanks Val!

DeleteCongratulations - I'll have to check out his magazine - the enamel work is wonderful !

ReplyDeleteThanks Deborah.

Deletehello ...love your jewelry

ReplyDeleteexcellent work !!